-

About Us

About Us

The word “Amicogen” consists of the meaning of friend, “AMICO”

in Latin and of gene, “GENE”. We developed innovative biocatalysts

and proteins by applying our proprietary i DNA Evolution™ Technology.

We are a “Bioengineering company just like a Sincere Friend”

who contributes to the human health and the preservation of environment. Amicogen is the representative Industrial Biotechnology Company in Korea

Amicogen is the representative Industrial Biotechnology Company in Korea

and wants to contribute to the protection of human health and the environment. -

R&D

R&D

Amicogen Biotech R&D Center is expanding its R&D field based on

bio-platform technology, and researchers account for 30% of all employees.

We will lead the Industrial Biotechnology to develop new technologies

that can drive the development of humanity and society,

one step further than others. Amicogen continues innovative research

Amicogen continues innovative research

and development for its first and best products. -

Products

Products

Amicogen has developed Special Enzymes for industrial and pharmaceutical products based on the i DNA evolution™.

We want to contribute to the sustainable growth and lifelong health

of humanity by developing New Bio-Ingredientfor Health functional foods

with Special Enzymes and Protein Purification Resin. Amicogen develops Bio Products and

Amicogen develops Bio Products and

New Bio-Ingredients for Health functional food. -

Investors

Investors

As Amicogen started as a bio-venture company, we have focused on

the core competence of R&D and are pursuing sustainable growth

in innovative technologies and products. To increase the value

of enterprise and shareholder, we are continually strengthening our core competencies such as specialty enzyme business, healthcare, protein

purification resin business and others. Amicogen strengthens key capacities

Amicogen strengthens key capacities

to increase enterprise value and shareholder value. -

Media

Media

Amicogen promotes various activities to realize the value of contributing

to the protection of human health and the environment.

Amicogen is positioning itself as a global biotechnology company

through growth and leaps to create new values. You can find various looks and news of Amicogen

You can find various looks and news of Amicogen

taking the initiative in the global bio industry. -

ESG

Sustainable management

Amicogen has developed bio innovative technologies and operated the businesses that consider humankind and environment from the perspective of sustainability for the past 20 years. We will continue sustainable development based on Amicogen's environmental soundness, social responsibility and sustainable innovative technology.

Amicogen wants to contribute to the protection of human health and the environment.

Amicogen wants to contribute to the protection of human health and the environment. -

Careers

Careers

Amicogen produces new technologies and values based on

creative thinking and constant technological innovation through human

oriented management. We do our best to ensure that talented individuals

with unique skills and abilities can demonstrate their abilities

according to the nature of their duties. We are waiting for Amicogen people,

We are waiting for Amicogen people,

who will open new values and a bright future. -

CONTACT

Careers

Amicogen produces new technologies and values based on

creative thinking and constant technological innovation through human

oriented management. We do our best to ensure that talented individuals

with unique skills and abilities can demonstrate their abilities

according to the nature of their duties. We are waiting for Amicogen people,

We are waiting for Amicogen people,

who will open new values and a bright future.

R&D area

R&D

Amicogen Biotech R&D Center researches various fields.

We will continue the innovative R&D for the first and best products.

we lead the research of specialized enzymes in different fields.

As there are increasing needs for alternative energy due to the depletion of oil, researches and commercialization of biodiesel are carried out in the industries. Amicogen promotes to develop enzyme process that can produce environmentally-friendly biodiesel. Amicogen Biotech R&D Center conducts research in the field of commercialization, such as optimization of fermentation conditions, production and safety experiments. In addition to the technical verification in the market, we strive to commercialize them as soon as possible.

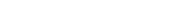

we develop new enzyme-based bio materials, fermented, natural materials and so on.

We focus on the development of chitinase and improve the productivity of the enzyme by about 2000 times in improving the mutant strain and with the commercialization of “natural N-acetylglucosamine (NAG)” which we export it to Japan and the US as well as domestic sales. Using the differentiated enzyme technology, we produce and sell D-chiro-inositol / Pinitol, materials for the prevention and amelioration of natural hypoglycemic/metabolic diseases and collagen peptide / collagen tripeptide, which is a cosmetic material (easily absorbable Nano-collagen and collagen- tripeptide with superior functionality), chitosan, which helps diet by adsorption of body fat, KeyClean, which is a natural preservative, diffuser lactic acid bacteria (BP2) with excellent reliability and chitosan oligosaccharide as an alternative to antibiotics from feed .

Amicogen’s Healthcare Research Center secures various basic research results of our materials through open innovation (joint research and development) with government-funded research institutes, university research institutes, and bio venture companies, and has scientific clinical trials results based on safety and human efficacy evaluation. We have been promoting our R&D competitiveness for the approval of certified functional ingredients.

We promote the branded business (K-nutra, KeyClean) and the ODM/ OEM business that manufactures functional health products and food by using Amicogen's new materials and selling directly to consumers. We plan to expand the development of consumer products (B2C products) by integrating enzyme technology into the development of various new high added value materials.

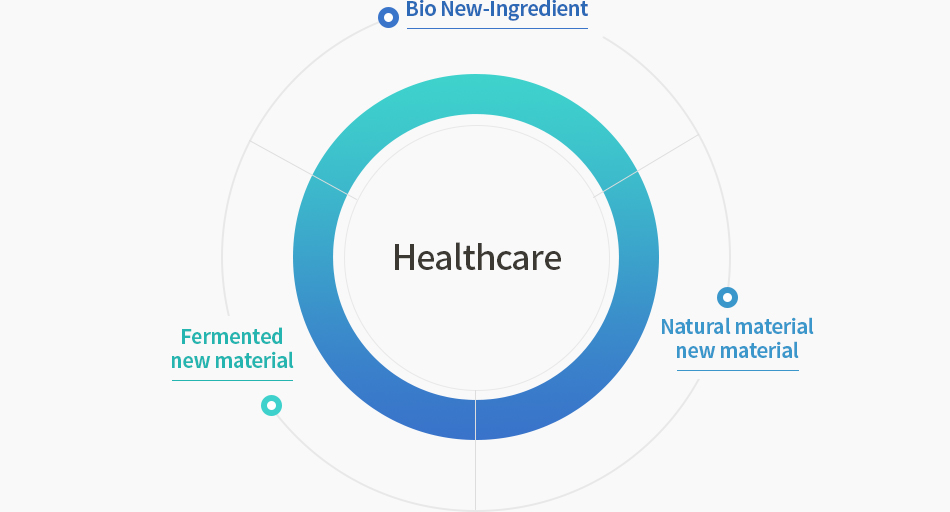

of metabolite mass production technology by controlling microbial metabolism.

The success of our new technology has the advantage for enzyme production, purification, the use of carrier and the reduction of immobilizing cost and is expected to contribute to the production of raw medicines, 7-ACA, intermediate 6-APA and Spinosad, an insecticide by means of the direct fermentation technology in the above.

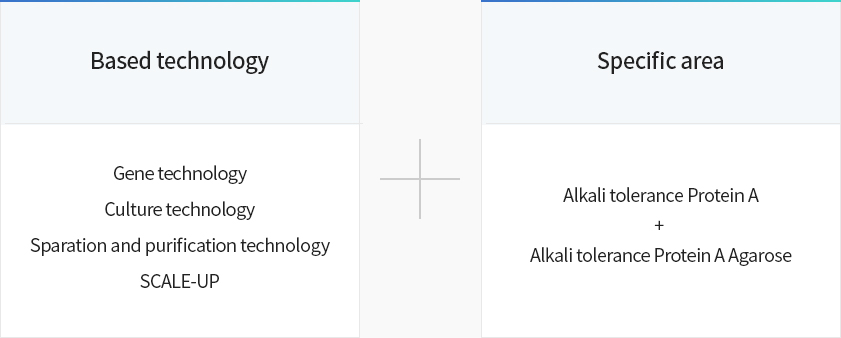

customizable resins for biologics and biosimilar.

Amicogen Protein Purification Laboratory has completed the development of protein A, protein G, protein L and protein A/G resins and has worked with foreign institutions to publish a competitive range of protein cleaning resins. We plan to expand the scope of this project by securing GMP and ISO certified manufacturing facilities for protein A resin that can be used in biopharmaceutical companies.